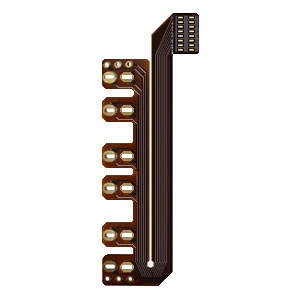

Flexible Circuits

| Applications |

| 1. Mobile |

| 2. Automatic doors |

| 3. LED lighting systems |

| 4. Automotive |

| 5. Aerospace |

| 6. RF-microwave |

Applications for Flex circuits include products featuring repeated flex cycles (cellular phones, automatic doors).

They are also being used as connectors for LED-based lighting systems. Often, there are two components:

- Metal substrate LED PCB

- FR-4 based digital driver PCB

Sample Boards

To view examples of this technology, scroll down and mouseover thumbnail images.